| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Brand Name : XYMJ

Model Number : Customized

Certification : ISO 9001:2015

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2000 kilograms per month

Delivery Time : 7-15

Packaging Details : Inner packing: wrapped by bubble bag,foam. Outer packing: standard export carton

Grade : YG6,YG6X,YG8,YG11,YG11C

Application : Mining Drilling

Size : Customized

Advantage : Factory Price

Product Name : Tungsten Carbide Rock Drill Bits

Shippment : DHL,FEDEX,UPS

Wear Resistant Parts Drill Bit Inserts Cemented Tungsten Carbide Dome Buttons

Cemented Carbide Buttons Advantage

Carbide (tungsten carbide) is used in numerous industries including mining, road construction, metal tooling, machining shops, and in various pieces of equipment where a metal harder than steel is necessary. Tungsten Carbide Buttons are always mainly used for rock, geological, coal mining, and oil field.

High hardness wear Resistant tungsten cemented carbide flattop buttons for mining bits advantages are a belows:

1. Using over 99.95% high purity tungsten carbide powder,it has a better strength and hardness,thereby a longer service life.Taking isostatic pressing precision machine,our drill button has a uniform density,and do not break easily.

2. Sintered by overvoltage sintering furnace,the carbide button are 24% more abrasive resistancing.

3. Grinded by centerless grinder,its has precis measurement.It's tightly welded,do not drop from drill.

4. It is using in making down the hole drill bit,ball nose drill bit,pillar drill bit lamp.

Grade List

| Grade | Co% | Density (g/cm2) | Hardness (HRA/HV30) | TRS (N/mm2) | Application |

| XD05 | 5.5 | 14.9-15.1 | 1380-1500 | ≥2800 | High hardness and wear resistance, suitable for making various parabolic buttons. |

| XK05 | 6.0 | 14.82-14.98 | 1370-1490 | ≥2300 | Suitable for making various sizes of buttons with fine resistance to impact and wear for drilling soft and medium hard formations at a higher speed rate. |

| XD10 | 6.2 | 14.80-15.00 | 1320-1470 | ≥2000 | High toughness, suitable for making buttons for high air pressure DTH bits drilling medium hard and hard rock formations. |

| XD10B | 6.5 | 14.75-14.95 | 1300-1460 | ≥2300 | Mainly for making buttons for low air pressure bits in mining. |

| XD20C | 7.0 | 14.7-14.9 | 1320-1450 | ≥2500 | With more cobalt content and toughness than that of grade YK05, it is a tougher alternative to grade YK05 to avoid risk of breakage of bits at high speed drilling rate. |

| XK10.5 | 7.5 | 14.7-14.85 | 89.0-90.5 | ≥2600 | Mainly for making buttons for DTH bits in various sizes of conical, parabolic and spherical buttons. |

| XK10 | 8.0 | 14.6-14.76 | 1200-1320 | ≥2340 | Mainly for making buttons of medium and small sizes for bits drilling soft and medium hard rock formations, also for making inserts for other drill bits. |

| YG8C | 8.3 | 14.55-14.75 | ≥87.5 | ≥2000 | Mainly for making buttons of medium & small sizes for drilling soft and medium hard rock formations. |

| Shape &Code | Picture | Drawing | Size | ||

| D(mm) | H(mm) | h(mm) | |||

| Ballistic compact |  |  | 7.4-29.7 | 10.0-32.0 | 3.7-13.0 |

| Spherical compact |  |  | 4.4-28.6 | 6.0-38.0 | |

| Conical compact |  |  | 5.4-25.4 | 7.0-42.0 | |

| scoop compact |  |  | 8.3-32.6 | 13.0-52.0 | 4.7-22.5 |

| Ballistic Wedge compact |  |  | 8.0-30.5 | 10.0-40.0 | 3.5-16.3 |

| Ballistic Wedge compact |  |  | 18.4-25.4 | 30.0-42.0 | 11.7-18.0 |

| aerofoil compact |  |  | 10.0-22.8 | 15.0-35.0 | 4.8-9.2 |

| special head preform |  |  | 11.15-12.84 | 13.7-16.2 | 8.5-10.4 |

| special head preform |  |  | 11.15-14.35 | 13.5-10.7 | 7.5-19.7 |

| special head preform |  |  | 10.2 | 14.6 | 9.4 |

| special head preform |  |  | 18.0-24.0 | 10.0-35.0 | 22.0-30.0 |

Details For Carbide Flattop Buttons

| Type | Dimensions (mm) | Angles | |||

| D | H | e | α° | βº | |

| P7.27-F2 | 7.22 | 7 | 1.5 | 45 | 18 |

| P8.27-F2 | 8.25 | 6.9 | 1.5 | 45 | 18 |

| P9.68-F5 | 9.62 | 8.5 | 1.5 | 45 | 18 |

| P10.29-F2 | 10.25 | 9.5 | 1.6 | 45 | 18 |

| P10.28-F2 | 10.25 | 8 | 1.6 | 45 | 18 |

| P10.310 | 10.35 | 10 | 1.5 | 30 | 30 |

| P5.25-E05 | 5.2 | 5 | 0.5 | 45 | 18 |

| YP11.39-E15 | 11.3 | 9 | 1.5 | 45 | 18 |

| YP9.28-E15 | 9.25 | 8.1 | 1.5 | 45 | 18 |

| YP5.27-E25 | 5.2 | 7 | 2.5 | 18 | |

Product Application Scene

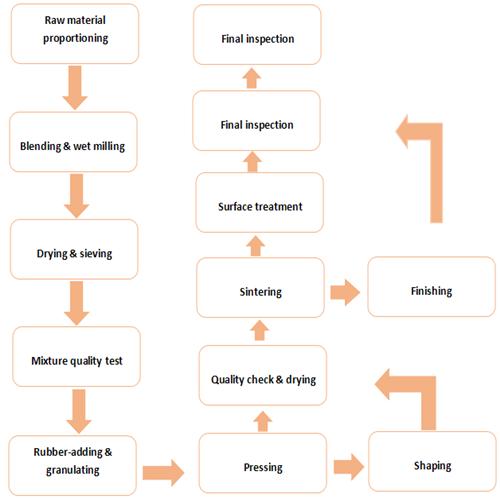

Production Process

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q4: What is your terms of payment ?

A4: Payment<1000USD, 100% in advance. Payment>1000USD, 30% T/T in advance ,balance before shipment.

|

|

High Hardness Mining Drilling Tools Cemented Carbide Flattop Buttons Wear Resistant Images |